Miscellaneous

Load Monitoring

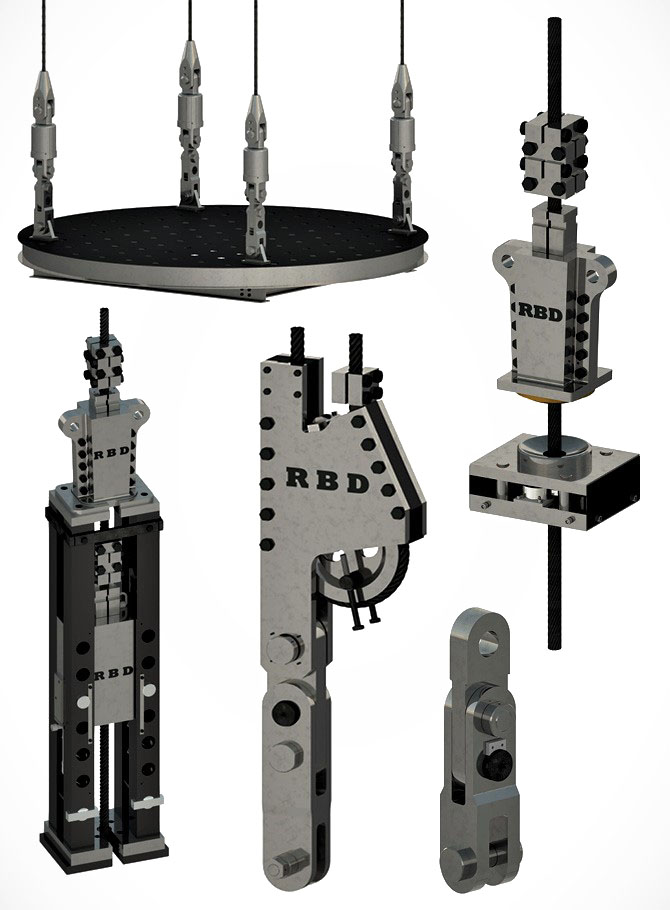

Reliance Barker Davies offers many unique designs for various load monitoring applications.

Load links are commonly incorporated within a “slack rope” detection system for hoist rope applications. Incorporating a load pin has several advantages. Firstly, a load pin has a highly reliable signal output. Secondly, load pins are preferred in harsh shaft environments due to their resilience against corrosion, water, and contaminant build-up; especially when compared to magnetic switches which are more susceptible to seizing or electrical connectivity failure. Lastly, load pins are easily replaced within the RBD components that they integrated with.

In guide rope applications, load pins are commonly incorporated within RBD CCM Tensioning Systems. Alternatively, RBD also offers load monitoring “seats” for suspension glands for integration with Cheeseweight Tensioning Systems. The output of either load monitoring system is commonly connected directly to the hoist PLC and programmed as a hoist trip in the event of slack guide-rope detection.